The industry is a huge energy user. Worldwide, it is responsible for a quarter of annual energy consumption and generates nearly 40% of energy-related gas emissions. In all its forms, much of the cost of industrial production is energy. To keep their businesses sustainable in the face of increasing costs, resource limitations, and environmental regulations, owners and operators must reduce energy consumption. In many industries, they have already made significant investments to achieve this. But they have not yet fully exploited the hidden potential of a simple solution – a heat recovery system.

Heat and its application areas

Heat is the foundation of almost everything in our lives. You have probably found that out in practice. For instance, when your milk is spoiled because your fridge wasn’t working properly.

On the other hand, if we only use the heat provided by the sun, large parts of the globe would be uninhabited. Depending on the geographical location and the season, artificial warming and heating are required. A typical example is producing heating for our households, etc.

Also, there are many other technological and industrial processes that are only possible with the supply of heat. This is the case with cooking and cleaning processes or using in the food and beverage production, etc. Besides, in many other branches of the industry, such as the paper industry, the construction materials industry, the chemical industry or the textile industry, many processes take place exclusively by bringing the heat required to perform the process.

Water and water vapor as heat exchangers

Heat is required for heating buildings and many other industrial processes. Imagine that each process or building must be heated separately. That way, you would probably produce more friction heat by grabbing for your wallet than many individual heating systems would produce. Why? All because of the lack of efficiency of such systems. Therefore, the required amount of heat is usually produced centrally and distributed through a means of transporting heat. They are so-called media or heat exchangers. This medium is transported to the heat energy consumers, where the heat is passed on. Afterward, with the help of the heat exchanger, the cooling medium returns to the central heat generator for reheating.

Water and water vapor as mediums of heat transfer have many favorable properties. Some of these properties are high energy absorption and easy transportation. These heat exchanger media are available and environmentally friendly – unless you try to boil your garden with boiling water, which it probably would not survive

The boiling point of water at atmospheric pressure is relatively low. If temperatures of more than 100 ° C are to be produced, the heat exchanger medium must be pressurized. That will raise the boiling point. The simplest example of such an application is the express cooking pot. But, we have a very similar application in industry as well.

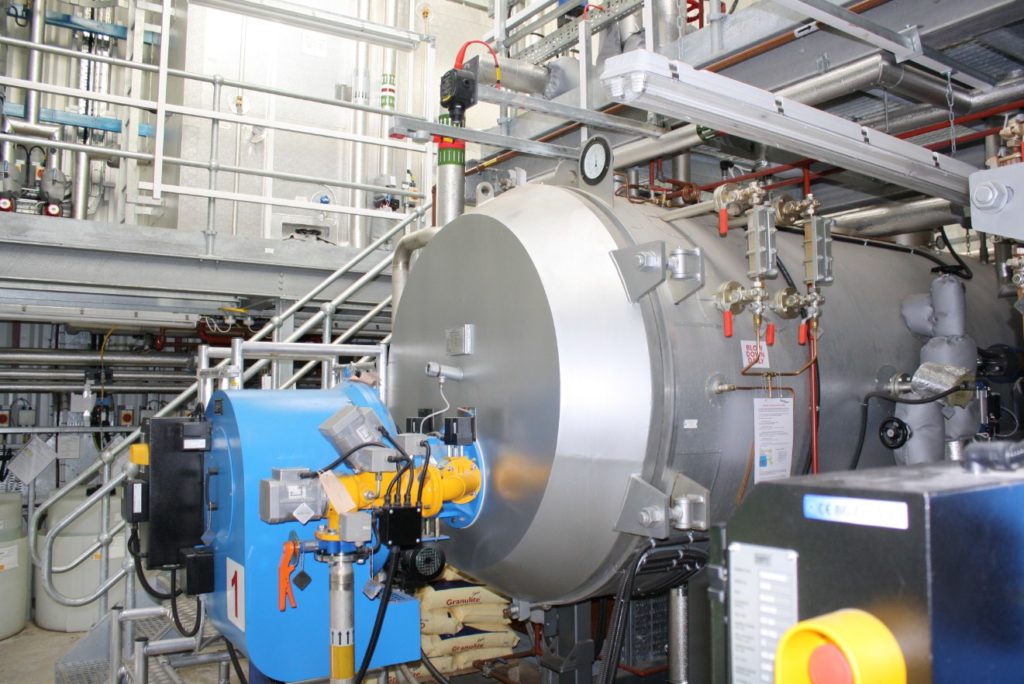

Industrial boiler construction

Industrial boiler plants can operate at significantly higher pressures than express pots. They are produced by welding from steel sheets up to 35 mm thick, which makes them workable under pressures up to 30 bar and higher.

The stable and robust construction of the boiler is also very important. If such a boiler cannot stand the operating pressures, it could make an explosion generating forces comparable to the force of one tonne of plastic explosive.

Each boiler can produce a thermal effect of up to 38 MW, which is roughly equivalent to the power of 500 VW Golf mid-range vehicles. Up to five boilers can be economically combined. One such industrial boiler filled with water and ready for operation can reach a weight of 165 tons, which corresponds to the weight of 120 VW Golf vehicles.

For these reasons, security systems must be taken into account. According to Exodraft, this includes regular maintenance, but also the use and replacement of genuine parts and accessories to ensure safety in the heat recovery process. This type of work is indulged to the professionals engaged in this business. These companies will supply both – controlling and providing the best solutions for your industrial production.

Interesting fact

At full load, a boiler of this size can convert 3000 liters of fuel oil or an adequate amount of natural gas into heat energy for heating or process operation. This amount of heat would be enough to heat more than 2000 single-family homes.

Application in practice

Industrial heating is quite similar to using household boilers. The main distinction is that industrial boilers are much larger. Therefore, their heating effect is sufficient for larger facilities or even the entire city districts.

The individual application examples are much more diverse. These generators are used in many industries. But is it all just heat and hot air and where exactly can it be used?

The food industry

Food must be heated or cooked frequently during processing. It is logical to conclude that this industry needs an abundance of heat.

Breweries

It is well known that beer consists of hops, malt, water and of course, Co2 Gas. However, before tasting, the beer must undergo a complex production process: the malt is ground and mixed with water. This blend must be heated to different temperatures for two to four hours. So industrial warming is again the key to the process.

Can you guess by which medium of the heat exchanger this process is carried out? This is done by using the steam previously produced in the steam boiler.

Afterward, the hops are added and the whole mixture is cooled down. After that, the yeast is added which speeds up the fermentation process. It certainly affects the taste of the beer too. Depending on the type, the beer has yet to mature, after which it can be packed or bottled. And then, there is the most enjoyable and refreshing part – drinking beer. After emptying, the bottles are normally returned to the brewery. Here, of course, they need to be cleaned up first before being refilled with beer again. This process also requires reheating. Amazing, isn’t it?

There are certainly other industries such as

- Automotive industry

- paint shops

- hospitals

- steelworks

- distilleries

- electrical industry

- pharmaceutical industry

- tobacco industry

- Ceramics industry

- Paper industry and many other