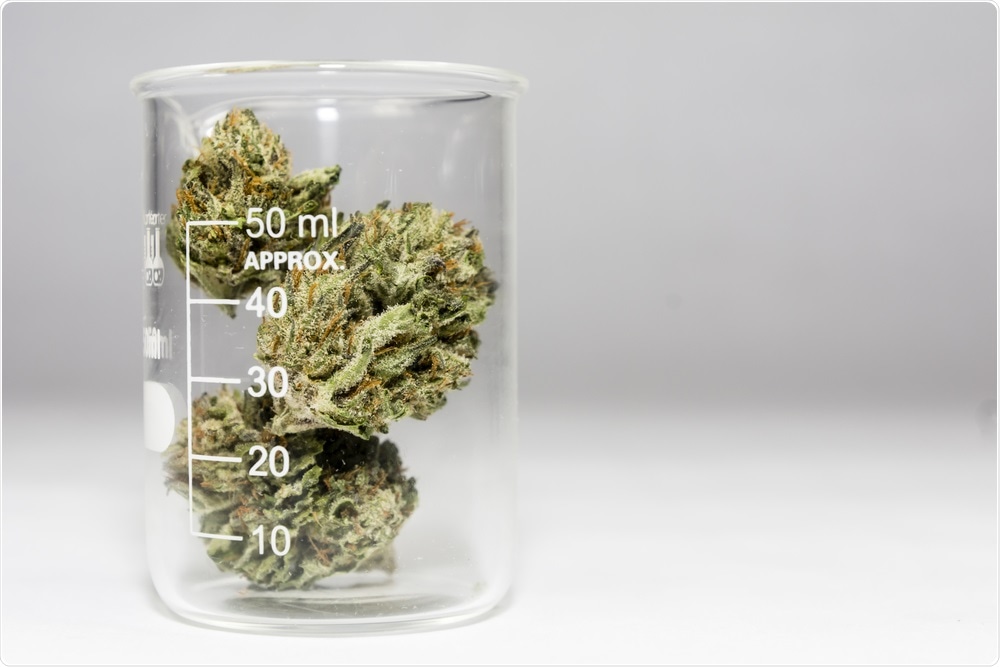

Cannabis sativa is the source plant for cannabis also known as medical cannabis or marijuana and hemp. The main distinction between medical cannabis and hemp is the potency level of the psychoactive compound tetrahydrocannabinols or THC.

For a product to be classified as hemp, the THC and in some states the total THC has to be less than 0.3% on a dry weight basis.

In the US thirty-seven states legally accept the use of medical cannabis and recreational cannabis. The rest of the states don’t view the possession of cannabis plants with concentration levels of more than 0.3% THC as a legal act.

Scope of the cannabis market

The cannabis market size is increasing and valued at USD 12 billion with a double-digit growth percentage that is enviable for any other asset class. The market for medical and industrial cannabis use is so large that the world’s best investment conferences are attracting more people to cannabis investment booths than other asset classes and investment opportunities.

With ease in regulations, a growing acceptance, and willingness from stakeholders to try their hand at either growing or using cannabis as a base product, the need for a cannabis testing lab has increased.

With proposals to ease the regulations in other states, the cannabis market size in the US is bound to see some windfall growth numbers. Even without complete relaxation, cannabis will remain an important agricultural crop when grown for industrial hemp requirements.

The hemp industry offers sustainable solutions for breathable fabrics that will impact the fast fashion industry and offer solutions for the next generation who need to revive the planet. Hemp is used in dietary supplements, veterinary calming solutions for pets, the packaging industry, and a toughened fiberglass that can sustain high pressure.

The number of products that can be made from cannabis plants grown for hemp requirements are several and offer many SKU options for anyone looking to make hemp-based products for commercial consumption.

Anyone who wants to deal with the hemp or cannabis-related industry needs to consider testing their products through reliable labs. Though this is not mandatory under the legislation of state or federal laws, it offers other benefits like establishing the potency level that will render the product fit to be categorized as hemp or needs to be destroyed.

Reasons for testing cannabis

Lab testing of cannabis though not mandated under any law is still a business practice requirement. This is because everyone cannot manufacture and sell cannabis used for medical and recreational purposes as it contains a higher concentration of THC and cannabinoids.

To ensure that the cannabis cultivar used for hemp-based products is in line with recommended potency level and is a consumable product, the following parameters have to be tested using appropriate testing methods:

- Potency

- Terpenes

- Microbial residue

- Pesticides residue

- Harmful elements

All these parameters are required as most hemp products are consumed in human and veterinary diets. Agro-based products need to go through these checks from a lab with good track records and experience.

Let’s check the methods used in cannabis testing for various reasons:

1. High-performance liquid chromatography

To establish the potency for safe consumption for patients and hemp users, cannabis cultivars have to identify the cannabinoid for its purity and concentration. This is established through HPLC methods as cannabis potency levels change with the growth phases of plant growth.

HPLC method allows the separation and identification of the cannabinoid compound through pressurized liquid solvent containing the mixture. In these methods, sample components are separated by pumping a high-pressurized liquid and collected through a column that has absorbent solvent. Every chemical compound has a point at which it disintegrates and reveals its true and purest form.

2. Gas chromatography

Gas chromatography uses vaporization methods by converting the acid forms of free cannabinoids through a decarboxylation method. Sometimes the conversion is not complete due to varying temperatures and injector parameters.

For this reason, pre-heating the sample before analysis offers accurate conversion with reliable results. Gas chromatography or GC is preferred by some testing labs as it is a simple and quick process in comparison to HPLC.

3. Thin layer chromatography

Isolation of cannabinoids, terpenes, and other bio and chemical toxins can be conducted through thin-layer chromatography. Non-volatile compounds are separated using this process where an absorbent substance is used to cover a glass or aluminum foil. Silica gel, cellulose, or aluminum oxide is used as absorbent material

3. ELISA and PCR testing

Microbial contamination is a huge problem in food and plant-based product processing. Enzyme-linked immunosorbent assay or ELISA kits are used to test mycotoxins from microbial and pathogenic presence in the cannabis sample. Real-time PCR tests also detect the presence of pathogens.

Preparation of samples

In any lab testing specifically, one that involves structural changes when exposed to light or air and is prone to decomposition, it is necessary to clean the sample. This step is necessary, as from the stage the sample is collected unless it has been sourced using the recommended parameters and stored at the right temperature, it is not easy to identify the elements of the compound.

Standard procedures

The standards and certified reference material or CRMs provided by the lab distinguish its reports from another lab testing the same sample. Due diligence before assigning the testing procedure to a lab is necessary as the CRMs used by a lab are preferred if designed and verified for accuracy. It is recommended to choose labs that offer CRMs following ISO guidelines.

Conclusion:

Hemp was used extensively in ancient civilizations. But early 1900s legislation changes and the recent easing of these laws still bear the risk factors of general acceptance by the common public. To establish a brand’s integrity it is necessary to follow a few parameters that involve following the industry’s best practices.

Testing of cannabis mitigates the risk in the business as the cultivators understand the stages in which the THC concentration in the cannabis plant increases and simulate the plants to grow in a manner where the psychoactive compounds are less in concentration.