After the pandemic, the need for medicines and supplements increased multifold. Pharma companies started producing capsule-based drugs and supplements. It made capsule-filling machines a game-changer for the pharmaceutical and superfood industries.

There are different types of capsule-filling machines available in the market. Liquid capsule filling machine provides a high-yielding and profitable medium for filling capsules with medicines that are in the form of liquid.

Types Of Liquid Capsule Filling Machines

Liquid Capsule Filling machines are a type of appliance that gets used in the pharma industry to fill liquid formula into capsules. This appliance utilizes advanced technology that helps fill the required amount of liquid medicine, maintaining the quality and correct dosage in the capsule. Different types are:

Manual Machine

Manual liquid capsule-filling machines are appliances an individual can efficiently use, and they get used in companies requiring the correct medication dosage.

The machine is suitable for small to medium batch requirement needs. This appliance gets used in industries like ayurvedic, herbal, nutraceutical, pharmaceutical, and many others.

They are manually operated and use a dropper to fill the liquid in the capsule. They produce capsules as per the user’s specifications.

Semi Automatic Machine

Semi-automatic liquid capsule-filling machines are less reliant on humans when compared with manual filling appliances.

They ensure faster, secure closing and ejection of liquid-filled capsules. The liquid could get added into the capsule through an automatic feeding mechanism that helps fill the exact weight variation, ensuring high production.

Even though these appliances automatically fill the liquid in the capsules, someone must manually load and unload the sealed capsule from this machine.

It combines a few characteristics of manual and automatic filling machines.

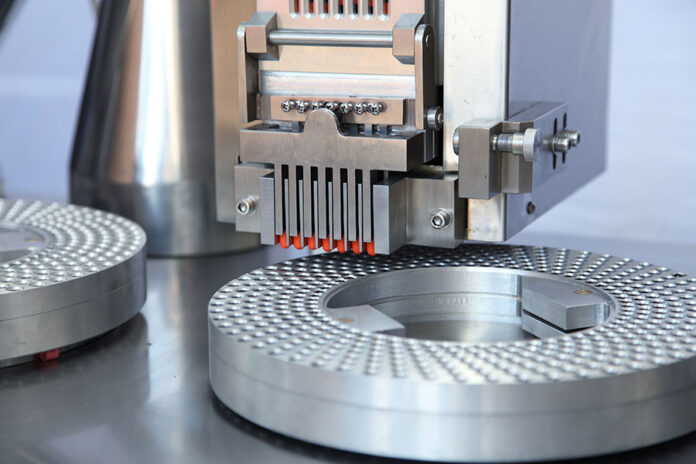

Automatic Filling Machines

An automatic liquid capsule-filling machine is developed to fill the capsules with liquid medicines without an operator.

In the pharma industry, these automatic fillers produce large quantities of capsules. These appliances can fill any combination of liquids as per the specification into the capsule’s body.

When a dust collector, polishing machine, damaged capsule checker, or empty capsule ejector gets added to this machine, then this automatic encapsulator makes a complete system.

The pharma sector requires liquid-filling capsule machines to produce high quantities of capsules in a contamination-free habitat.

They include a fully automated system to load the capsules into the machine, fill liquid in these capsules, and then close them automatically.

Liquid Capsule Filling Machine Benefits

The capsule-filling machine is also called an encapsulation machine. It gets designed to fill the capsules having different formulas. They do provide a lot of benefits, and few are

Accurate Filling

They have high filling accuracy, and the capability and safety of the medicine are known only when the correct dosage gets filled in the capsule.

The automatic machine is more advanced than the manual and semi-automatic liquid capsule filling machine. It allows for accurate filling of the medicinal liquid in the capsules at high speeds.

The manual capsule filling machine gets manually operated by hand by an operator. It sometimes does lead to a difference in the weight of the ingredient filled into the capsules. Sometimes the variation could vary between plus or minus five to ten percent of the target weight.

Compared to the manual machine, a semi-automatic capsule-filling machine is more accurate. But still, these appliances do need some form of intervention manually. Their filling accuracy sometimes varies between plus or minus two to three percent of the target weight.

Automatic capsule filling is more accurate than manual and semi-automatic machines. The filling accuracy varies between plus or minus one percent of the target weight. The required dosage efficiency could easily reach precisely by reducing wastage, ensuring stability and constancy in the final product.

Increased Production

If the business plans to increase its production capacity and scale up its business, automatic machines are a good bet.

Manual liquid-filling capsule machines take several hours to fill the required number of capsules. It takes a lot of time.

Semi-automatic machines can fill in the capsules like an automatic machine, but it still needs manual human intervention at one stage or another, limiting the output in production.

With automatic machines, production is multifold in a shorter time. Technological advancements in automation increase the show and, at the same time, reduce labor costs.

Labor Costs

Using manual and semi-automatic machines will get costly as workers get involved in the production process. It will be expensive for the industry in the long run.

Whereas the automatic machine automates the production of the capsules without any need for workers in the production process, thus keeping the labor costs to a bare minimum

Hygiene Maintenance

For the safety of oral dosage in capsule form, hygiene quality should remain consistent. The automatic capsule-filling machines ensure that every capsule gets filled with the same hygiene ingredients.

Manual and semi-automatic filling machines get exposed to air, whereas the filling process in an automatic takes place in proportionate closed conditions.

The automatic capsule-filling machine’s cutting-edge design makes it safe to work in a hygienically controlled habitat. It ensures the purity of the final product without any contamination.

There are sensors in the automatic machines which inspect all the capsules, and if any defective capsule gets found, it gets rejected and ejected during the production process. It ensures all the quality standards set forth get adequately met.

Easy To Operate

The automatic liquid capsule filling machines are easy to operate as the staff could get trained quickly and speed up the skills to use this machine efficiently.

The manual and semi-automatic capsule-filling machine requires some technical training as they are cumbersome.

The automatic machine simplifies production by having user-friendly interfaces with touchscreens that effectively display clear instructions. Since they have sensors and control systems, they automatically monitor the filling process without requiring manual intervention.

Time Gets Saved

The automatic machines are elegant enough to handle the production process without any need for intervening manually, thus saving time in production.

The capsules and liquids must be loaded and inspected manually in a manual and semi-automatic machine, whereas production output is automatic in automated machines.

Versatile In Nature

Automatic machines are widely used in many industries worldwide as they are versatile. They handle a wide range of capsules in different sizes and weights. Also, they can get tuned to increase the production speed depending on the requirement and the material used.

They could fill different ingredients in capsules by slightly tweaking the system controls and filling them with liquids, pellets, granules, micro-tablets, and other combinations as and when required.

Even hard gelatin, soft gelatin, and vegetable capsules are suitable for filling using this machine.

Conclusion

The liquid-filling capsule machine provides many benefits to pharmaceutical and nutraceutical companies. These are cost-effective machines in the long run. Businesses looking to increase mass production and streamline it efficiently should invest in these machines.

These machines are upgradeable, and the business can quickly adapt to the new market demands that change whenever a breakthrough gets discovered. At the same time, it helps keep the company ahead of the competition.