Every day we use products that contain printed circuit boards, and these units allow every electronic device to work properly. They are relatively easy to manufacture, and they come with low costs. Finding the right service that will help you with the assembly is crucial if you want to be successful in your job. Note that when you cannot rely on the company that manufactures and assembles them, the electronic item will not work as required, and it will get damaged and broken in a short time.

The PCBs are the most important part of every device, and you need to spend enough time looking for the right service to collaborate with. Since there are hundreds, even thousands of companies who do this, it is hard to find the right one for your specific need. In this article, we are going to give you some tips for finding reliable low-volume PCB assembly services. Continue reading if you want to learn how to find the right company for you, and how to avoid those who will sell you bad products that will break right away.

1. Look for a company in the same area

The first thing we are going to talk about is proximity. Even though this is not the most important part of your vetting process, it is still better to collaborate with a business that will be able to do same-day shipment and delivery, than to have to wait for days, even weeks for your goods to arrive. Note that when you collaborate with a service that is local, you will be able to easily find out more about them, if they are reliable, and you can have meetings with them without issues.

Look for a company that is near you, and that will be able to provide the needed things. Note that if you cannot find one, it is not the end of the world, but when you do a search by location, you are going to narrow down your list and find the right business for you.

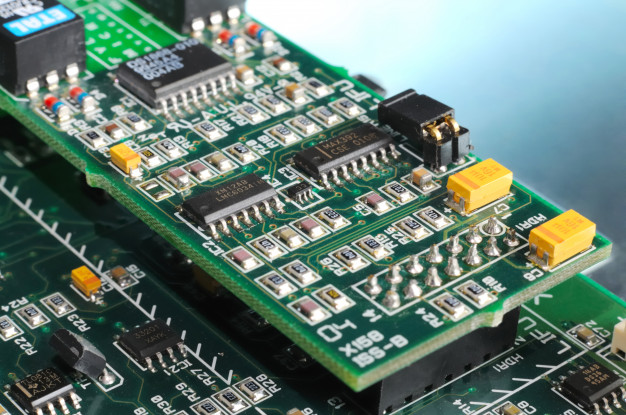

2. Check to see which materials they are using

When looking for a reliable service, you need to open their website and find as much information as possible about the materials they are using. Note that this information should be available on their site, but in case you cannot find it, you are free to contact their customer service and ask for more info on the products they are manufacturing and assembling.

Note that if they don’t want to disclose the materials they are using, you should probably continue your search. Know that a company that is trying to cut costs and save money when manufacturing a PCB is not the right place for you, and you should look for places that are not afraid to share this info, and who are proud of the things they are using. Nowadays, more and more companies are turning to green manufacturing, and the best services will provide items that are lead-free. For additional information check what experts from pcbonline.com have to say about why producing lead-free items extremely important, and how it affects the quality of the boards.

3. Price

This is something that we cannot disregard, and no matter how high your budget is, you certainly don’t want to spend thousands of dollars on something that you can buy for much less. Some companies will offer high-quality items that are going to be a bit more expensive, while other places will try to lure you in, and make you purchase low-quality goods just because they cost a fraction of the market value.

Quality is usually related to price, so don’t go for the business that offers goods that sound too good to be true. Try to wage in and see if the price is low because the boards are not good, or if they have a special promotion at the moment. On the same note, this does not mean that you need to purchase the most expensive things you can find, so try to find something that is in between. The best of both worlds would be a service that provides normal prices, with good quality. Compare the costs, and see if you can get a discount depending on the number of goods you are purchasing.

4. Are they following the guidelines?

When we think about a specific business and industry, we believe that everyone is following all the guidelines and regulations. PCBs are some of the most needed items in the world, and every company that produces them tries to make as many of them as possible. When there are not enough goods to present on the market, they risk losing customers.

Because of this, some businesses will try to rush things and get as many goods as possible without following the regulations. You should look for a service that will not compromise quality just to produce a larger quantity. If the company that produces them does not pay attention to the regulations, you risk ending up with goods that are going to break easily and won’t withstand the test of time.

5. Storage

The last thing we are going to talk about is storage. As we mentioned before, a large company can produce thousands, even hundreds of thousands of PCBs in one day, and they don’t ship them right away. Sometimes these items can be left in the factories for days, weeks, and even months. Because of this, a proper way of storing them is crucial.

Note that no matter how good the items are, and no matter how amazing the production process and used materials are if the goods are not kept properly, they are more likely to rust, break, or get damaged. Talk to the service about their storage facilities, and if possible, visit them and see how the items are kept.

They are supposed to be kept in dry and cool places, where there is no moisture, and where there is enough ventilation. If you cannot see this on your own, you should look for images from their facilities.

These things will help you find reliable low-volume assembly services, and it is going to be easier for you to pick the right one. Look for places that offer warranties and that are proud of the items they are manufacturing and assembling. Ask for return policies, and don’t forget to check reviews and recommendations.