A prototype can be said as a three-dimensional design of your vision and your plan. Making a plan before inventing or manufacturing anything is very important. A plan guides you throughout the manufacturing process so that there is a little or no deviation from what you have envisioned.

Creating a prototype before you start with your work is actually a fun activity and a rewarding step towards your goal. Developing a prototype makes you realize how and what is to be done using your creativity. It will make you use your talent and skills, which you believed and inspired you to develop the invention idea.

Before making a prototype, your idea is in your mind, which you can only explain to people with words. But when you make a prototype at your home or hire engineers, machinists, mechanics, seamstresses, etc., you will be satisfied and excited to see your intangible idea taking a definite shape in real life. It will make your work of explanation easy in front of the inventors or anyone you are trying to explain about your new invention or a new product you plan to manufacture.

If you are searching for a partner to develop your electronics, Axonim provides you with confidentiality, competence, and quality of work, comprehension, enthusiasm, decent work, and trust.

Thinking of a prototype, what it must look like?

Firstly, it entirely depends on the idea you are thinking of going ahead with. Secondly, your budget plays a huge role in your prototype; it depends on your finances and the goal you want to achieve. If it is possible, a handmade prototype will be the best option, no matter how basic and straightforward it is. It will give you a clear image of your product.

Suppose you do not have much budget for your prototype and want to make it for demonstration purposes to your clients and investors. In that case, you can use old household items or lower price products and make a rudimentary model.

Ultimately, on the off chance that you choose to push ahead with your manufacturing idea, you’ll most likely need what’s known as a “pre-production” or a prototype model – particularly if you intend to fabricate it yourself instead of license it. However, as an initial step, a homely constructed “presentation” model can give you a decent running beginning.

A prototype provides many advantages apart from giving you an idea about your plan.

1. Prototype helps you test and rectify your plan and design

The model empowers you to try and refine the use of your project. Indeed, your thought works totally in principle. It’s not until you start making it that you’ll experience defects in your reasoning. That is the reason another incredible motivation to build up a model is to test the usefulness of your thought. You’ll never realize the plan issues and difficulties until you start taking your ideas from the world of theory to the world of reality.

2. It helps you check the performance of various products and materials

To make a budget-friendly yet long-lasting product, you need to first check which material to use. To fit everything in a miniature model reduces the cost, and it helps you escape the defects or the loss of money, which can result after manufacturing with faulty materials. Take an example where you wanted to use a metal, but after making the prototype, you realized that plastic makes the final product lighter and easy to carry and is a better fit in your budget. This way, it will help you come up with the defects in your theoretical plan.

3. A pre-made model will help you describe your theory more effectively

You need to define your plan to your marketing team, business partners, engineers, attorneys, investors, packaging team, and many more people—all those who will be a part of your business or manufacturing. A theory may seem perfectly fine to you but may not be enough for other people as they cannot envision the real thing that is in your mind. Therefore a prototype model is highly recommended.

4. A three-dimensional vision of your plan will encourage others to take your project more seriously

When you go to a meeting with a ready-made model in your hand to give a presentation or to meet any professional, your half work is done, as they will separate you from many people who come up with a vague idea. You will present yourself as a professional person with a potentially good plan.

Developing Your Prototype

So since you realize that making a prototype is a crucial part of your manufacturing process, how precisely do you push ahead and do it?

This step of your whole planning, processing, creating, directing is the best step. As you will know what you have to do and how it needs to be done. You will put your idea on a design for the first time. Creating a prototype will clear many questions from your mind, such as How can I? Which options to choose from?

There are no rules when creating a prototype; it’s just for you to understand and make people understand your plan. You can make a model by your hand using household materials, use your ideas and bring in your talent and skills.

If you want to create your prototype as close as possible to your plan and want to use metals, chemicals, textiles and take the help of engineers or a constructor or anyone, you must accept their help. This will give you a more accurate idea about your project and your marketing budget plan.

Let’s look into few steps to create your first product prototype:

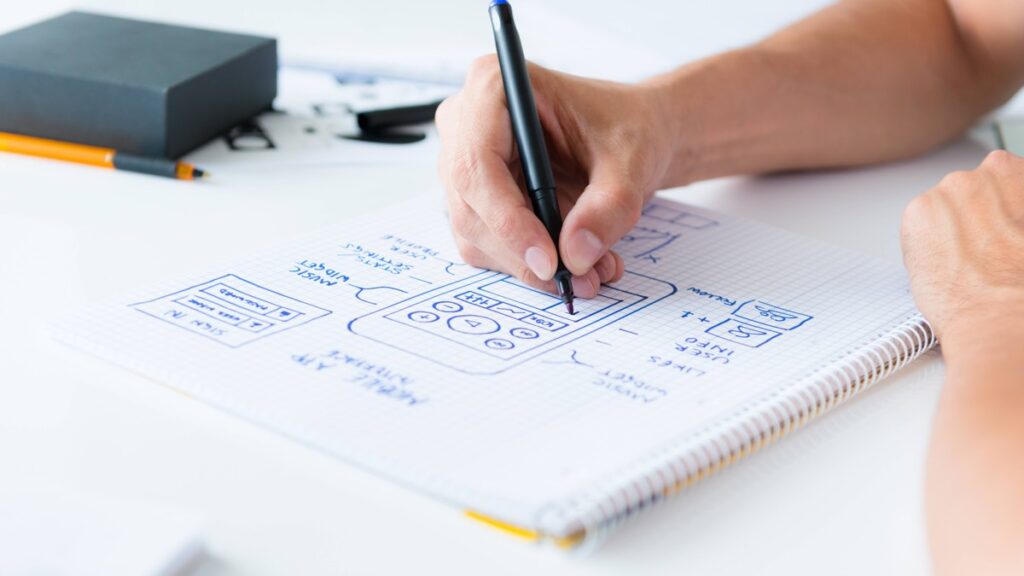

1. Creating a Concept Sketch

Before starting with your model, you must draw it on a page, and if possible digitally, this will make your work of creating a prototype easier.

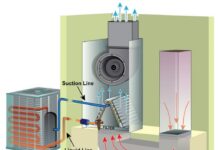

2. Developing a virtual prototype

A digital creation of your idea, giving it a 3D dimension, will visualize your plan from all angles.

3. Build a physical prototype

Once you have adequately visualized your plan from all the possible ways and angles, you can start creating your prototype. If you want, you can also go to a professional model designer.

4. Locate a Manufacturer

When you have a functioning model, you’re prepared to apply for a patent; notwithstanding, you should make the extra effort of finding a maker that can deliver your item at a production cost. On the off chance that your thought will be productive, you should have the option to assemble it at an expense that is low enough that you can cover costs without cutting excessively far into your income.