It is a fact the classic furniture will never go out of style. For many people, it can never come close in comparison with modern, state-of-art pieces. This is especially true for vintage pieces of furniture because each of them has its own history and a story to tell.

Obviously, classical furniture is still produced nowadays, but with one small difference. In the past, these pieces were all handmade, but today, there is a CNC machine that allows manufacturers to create the same pieces but even of higher quality and without much trouble. If you are thinking about investing in this machine, keep reading this article because we are going to give you some basic information about it and also provide you with a list of benefits i.e. reasons why you should get it.

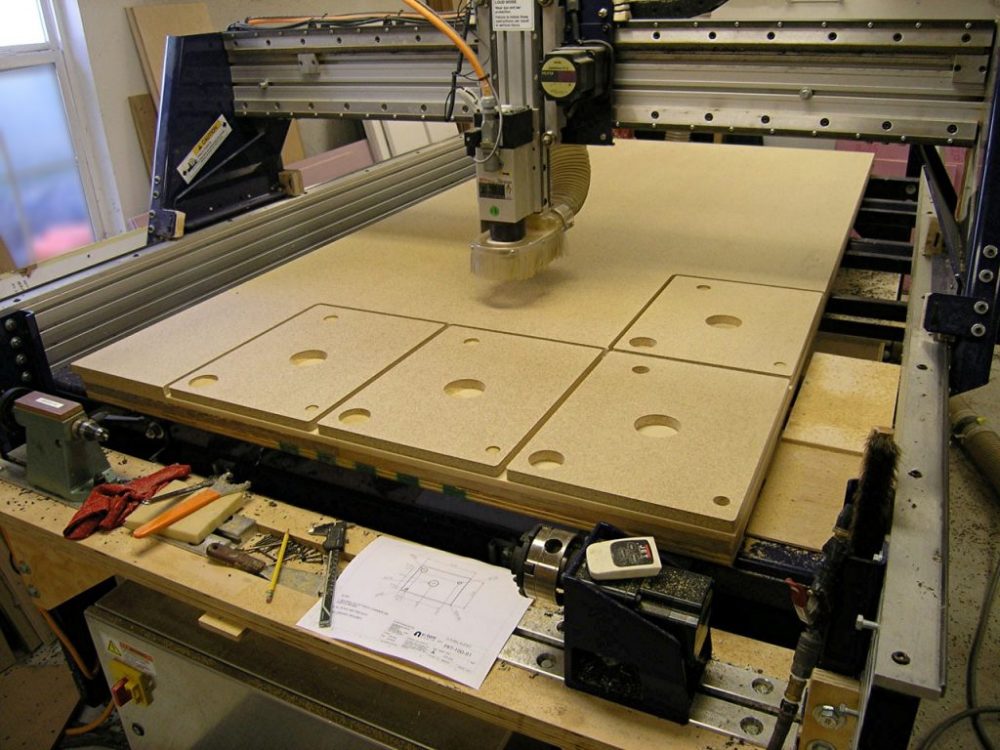

What is a CNC machine?

Firstly, let’s begin by introducing you to this piece of equipment. In a way, it is some sort of computer because it consists of a wood router and CAD software. This software allows you to create a 3D image of the furniture you want to make. You don’t only get to determine the style and design, but also the size of each part. What’s more, you can even add some small nicks that are going to contribute to that vintage vibe.

As you know, in the past, when numerous people would work on a single piece, some small damages couldn’t have been avoided. If you want to create some similar pieces of art, because that furniture is considered to be art today, you can always add some indentation into the software design.

Now that you have the completed design, the machine will do everything else. You can think of it as a top-notch printer that can make whatever you have envisioned.

What are the benefits?

Before we start listing other benefits, there is already one that is surely obvious to you and that it reduces the requirement of manpower. Is it really necessary to explain why using a ‘computer’ is beneficial? First of all, naturally, you and your workers won’t have to spend too much time perfecting the furniture.

This means that you will have more time at your disposal to focus on some other aspects of the business that are going to help your company grow. Secondly, this also means that you might not have to employ too many people meaning that you will save a significant amount of money. This is especially important for small startup companies where every dollar is important.

Precision

The first advantage that we are going to discuss is precision. We are sure that you agree with us – there is nothing more frustrating than cutting all the pieces only to learn that they do not fit perfectly together because some of them are too small or too large.

When you start working with this machine, these things won’t happen, simply because you will be able to put in the right dimensions into software, and the machine will cut them with extreme precision.

Adjustability

The second benefit that many manufacturers love is that you can make changes to the design easily. If you are a perfectionist you surely want every piece to be breath-taking and probably make a lot of small changes to the original design until you are satisfied with it.

Again, since this machine uses software not only can you without any trouble modify the piece however you want to, but you can also do this whenever you want to. In addition, this is especially beneficial if you work on manufacturing furniture commissioned by a client. We all know how easily they can change their mind, so when this happens, instead of altering some parts of starting the entire production from the beginning, you can easily add those modifications to the machine and its software.

Multi-functionality

One of the best features of this equipment is that is not only able to cut wood but also some other materials such as steel, plastic, and acrylic. This is a great thing because it allows you more freedom when it comes to the layout and mixing different kinds of materials. It only means that you can take the design to the next level. If you want to learn more about other beneficial features of this machine, click here.

Attention to details

As already explained, vintage furniture is considered to be art because of all the small details and even imperfections on it. Depending on the overall style of your work, you can mimic these. Clearly, we are talking about some tiny indentations that are going to add that special charm to the furniture.

Even more significant it is the fact that you will be able to create some unique designs that you probably couldn’t do otherwise. Carving these, depending on the composition can not only be complex, but it can also take some time.

Time-saving

This brings us to our next point – by using the CNC machine, you are going to save a lot of time. Once again, the entire process is automated which means that all you have to do is to input the layout and the machine will do the rest.

We can all agree that nowadays, time is of the essence. By investing in this equipment not only are you going to save time when it comes to your involvement, but you will be able to produce more pieces of furniture i.e. to speed up the entire manufacturing process meaning that you will be able to do more work.

Safety

After reading others, this advantage is an obvious one. As you probably know, working with wood and manufacturing, well, anything can be quite dangerous and accidents can happen occasionally. It is very simple. Since this machine doesn’t require almost any manpower, the chances of accidents occurring are significantly lower.

Cost-effective

This is the final benefit that we are going to mention, and let’s be honest, for many companies is one of the most important ones. Even though this investment can be quite pricey, it is going to save you and what’s more, earn you more money in the long run. When it comes to the former one, it reduces the requirement for more workers. In addition, as already mentioned, the machine accelerates the manufacturing process which means that you will be able to create more furniture and sell it thus increasing your company’s revenue.